Screwed Combined Air & Dirt Separators

¾", 1", 1½" BSP Brass - 2" Stainless Steel

Air & Dirt Free System Water Through a Single Device

The life and efficiency of a heating or cooling system is greatly dependent on the quality of the system water. Air and dirt problems cause frequent breakdowns and a huge increase in customer complaints. Corrosion, cavitation and component wear are consequences of air-saturated, dirty system water. Recurring problems and increased maintenance results in unnecessary costs and dissatisfied customers. There is a solution...

SUPAFLEX SCAD

Screwed Combined Air & Dirt Separator

A system without air is possible. There is a unique dual-purpose device that will remove air and dirt – down to the smallest particles – keeping the system free from air and dirt, permanently. It works differently to traditional filters, with less maintenance and fewer costs.

Benefits

- Improved efficiency

- Reduces the risk of system failure

- Increases component life

- Reduces oxygen-based corrosion and pump cavitation

- Quiet operation

- No bypass, isolating valves or replacement filters to clog and reduce pressure drop

- Dirt can be flushed while system is operating

The Air-Free & Clean Solution

An air- and dirt-free water system through one unit. Solves problems arising with air and dirt in water systems.

Deaeration

Deaeration describes the removal of dissolved gases from liquids such as air from water. When water is heated or the pressure is reduced, gas microbubbles are released into the system. Microbubbles can be the cause of major problems such as pump failure, corrosion and energy loss.

The Solution

The Supaflex SCAD combines the removal of air and dirt through a single unit. Installed at the hottest point in the system the unit will eliminate these microbubbles from heating and chilled water systems.

Install the Device for Optimum Performance

Microbubbles are mostly released when system temperature is highest based on Henry's Law. Henry's Law states that air is released from water as the temperature increases or the pressure decreases. For this reason, the Microbubble deaerators and dirt separators are typically installed

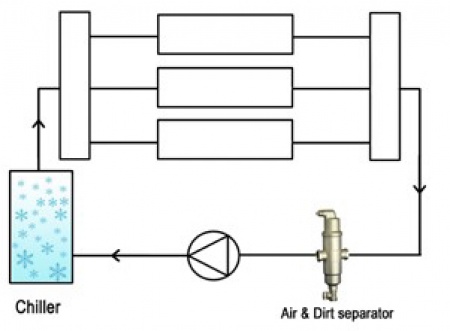

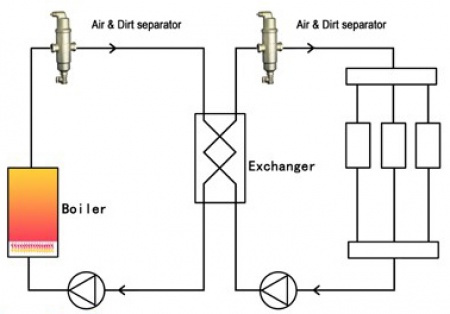

Installation Diagram

Chilled Water System

Heating System

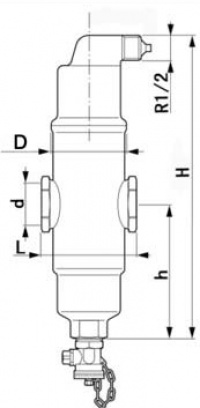

| Model | Size | H (mm) | h (mm) | d (BSP) | D (mm) | L (mm) | Flow Rate (m³/h) | Weight (kg) |

| SCAD-DN20 | 20 | 265 | 112 | ¾" | Φ 65 | 100 | 1.25 | 1.7 |

| SCAD-DN25 | 25 | 265 | 112 | 1" | Φ 65 | 100 | 2 | 1.7 |

| SCAD-DN40 | 40 | 265 | 112 | 1½" | Φ 65 | 100 | 5 | 1.7 |

| SCAD-DN50 | 50 | 332 | 137 | 2" | Φ 88 | 134 | 8 | 6 |

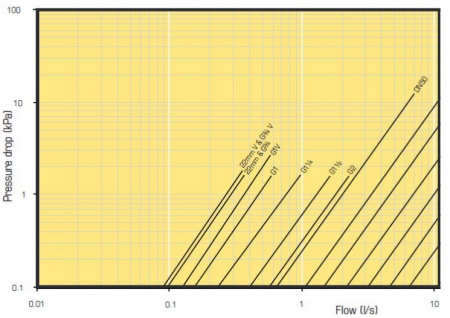

SUPAFLEX SCAD Separators Pressure Drop

Dirt Removal

The Supaflex SCAD is also used to remove dirt particles from heating and chilled water systems. When installed it will eliminate all dirt particles down to 10 microns

Features

- Greatly reduced commissioning times after initial fill

- Longer system life (through air and dirt elimination)

- Low pressure drop

- Bi-directional flow

- Max temp 110 °C

- Max working pressure 10 Bar

- Tested to 21 Bar

- Air collects in the air chamber before being automatically vented

- Large dirt collector ensures flushing frequently is only required in early stages

- Can be flushed while fully operational (no need to shut down)

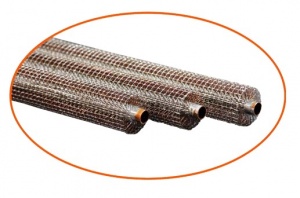

- An internal copper wire concentrator to aid removal of air and dirt

Location

This unit must be installed at the hottest part of the system. In a heating system this is the main flow from the boilers. The static head must not exceed 15 metres. In a chilled water system the unit must be located in the return, close to the chiller. Maximum static head must not exceed 10 metres.

N.B. If the static head is greater than these figures the efficiency of the unit is reduced. The maximum flow velocity through the unit is 3m/s. If these values are exceeded the efficiency is reduced.

Commissioning

The Supaflex SCAD requires no special commissioning. Maintenance will be required to remove trapped dirt and sludge; this is done by opening the ball valve at the bottom of the unit. The valve may be opened while the system is under pressure. Scalding is a danger at high pressures and temperatures. Ensure that the water is safely piped to a drain before opening the valve.

The system pressure will flush the dirt out – leave the valve open until the collected dirt has been flushed out and repeat this operation every few days. Once the water is clear, it may be possible to drain every six months or so, depending on the size and age of the system. Most of the dissolved air will be removed in a few days.

However this may vary from system to system. In large systems it may take several weeks. Dirt separators can only remove dirt that is circulating.

Drain Valve

All models are supplied with a ball valve for draining the collected dirt and sludge.

Other Larger & Associated Equipment

Supaflex also supply larger flanged units (50-600mm) both combined or as separate air and dirt separators. They can also be removable/demountable and magnetic. We also offer consultation on hydronic separators and vacuum degasser units with dirt separators (for high static heads only).

Pipeline Equipment

- Copper Expansion Bellows

- Axial & Articulated Expansion Joints

- Flexible Connectors For Pumps & Equipment

- Microbubble Air & Dirt Separators

- Chemical Dosing Pots

- Water Sample Coolers

- Magnetic Low Velocity / Loss Headers

- Fancoil Hoses & QRCs

- Inertia Base, Spring Anti-vibration Mounts & Spring Hangers

- Buffer Vessels - Horizontal & Vertical

- Vacuum Degassers

- Anchors & Expansion Joint Guides